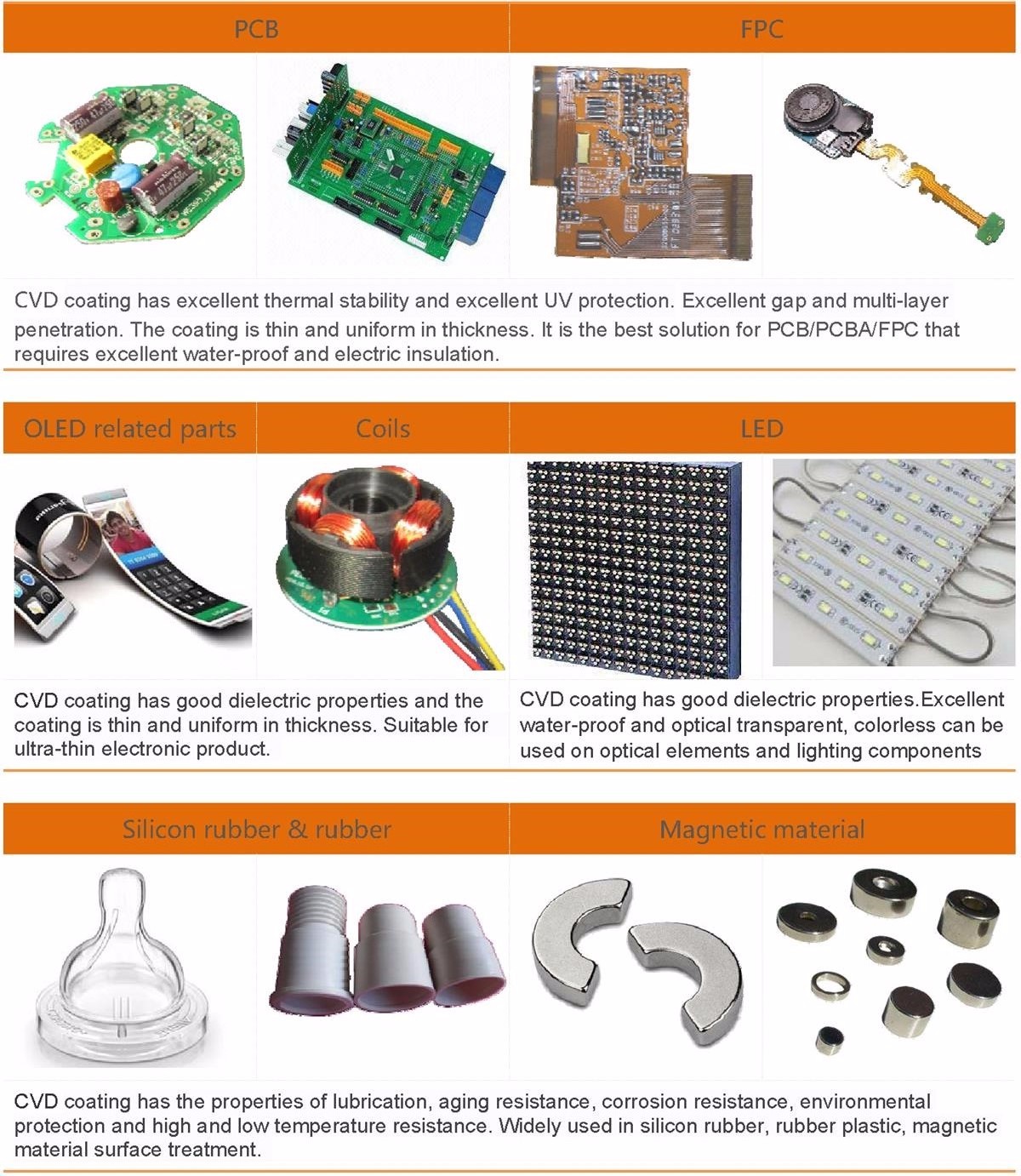

CVD is wildly used in aviation, PCBA, LED, magnetic material, sensors, silicon rubber, sealing element, medical equipment, precious cultural relics and etc.

bonding the frame and touch screen of various electronic products (such as mobile phone and tablet computer).It is alswidely used in the adhesion of glass,metal ceramic,rubber and plastics substrates in the microelectronics industry.

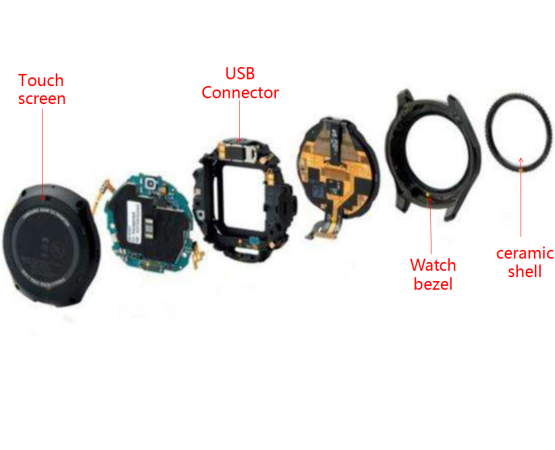

PUR hotmelt adhesive applied in smart watch and smart wear project:

1. Bonding the frame and touch screen

2. Watch bezel and ceramic shell

3. USB connector sealing

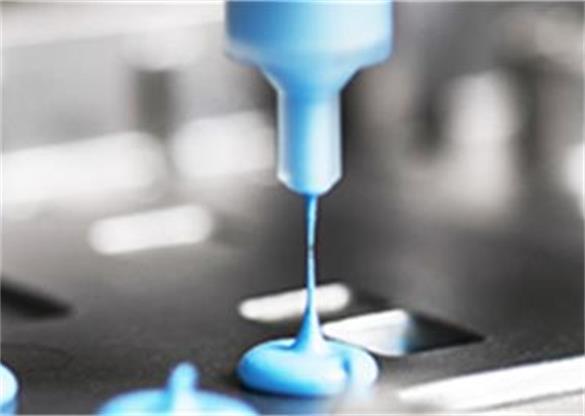

1. Coating and sealing of various electrical and electronic products and components.

2. Silicon pacifier, bottle, diving mirror, medical supplies and other finished products manufacturing.

3. All kinds of food grade mold materials and precision parts mold making.

4. Fiberglass, military, automobile and ship components mold manufacture.

5. High - grade simulation food, simulation cake mold and simulation sugar.

6. The easy design and rapid fabrication of high-precision prototyping.

7. Silicon dental, medical products, silicon wax figures, silicon dolls, silicon parts, silicon sealing ring, silicon rubber sheet and other silicon products and mold fabrication.

8. Precise casting equipment, carbon fiber composites, machine parts mapping.

Copyright ? 2015-2018 LPMS International Ltd. All Rights Reserved.