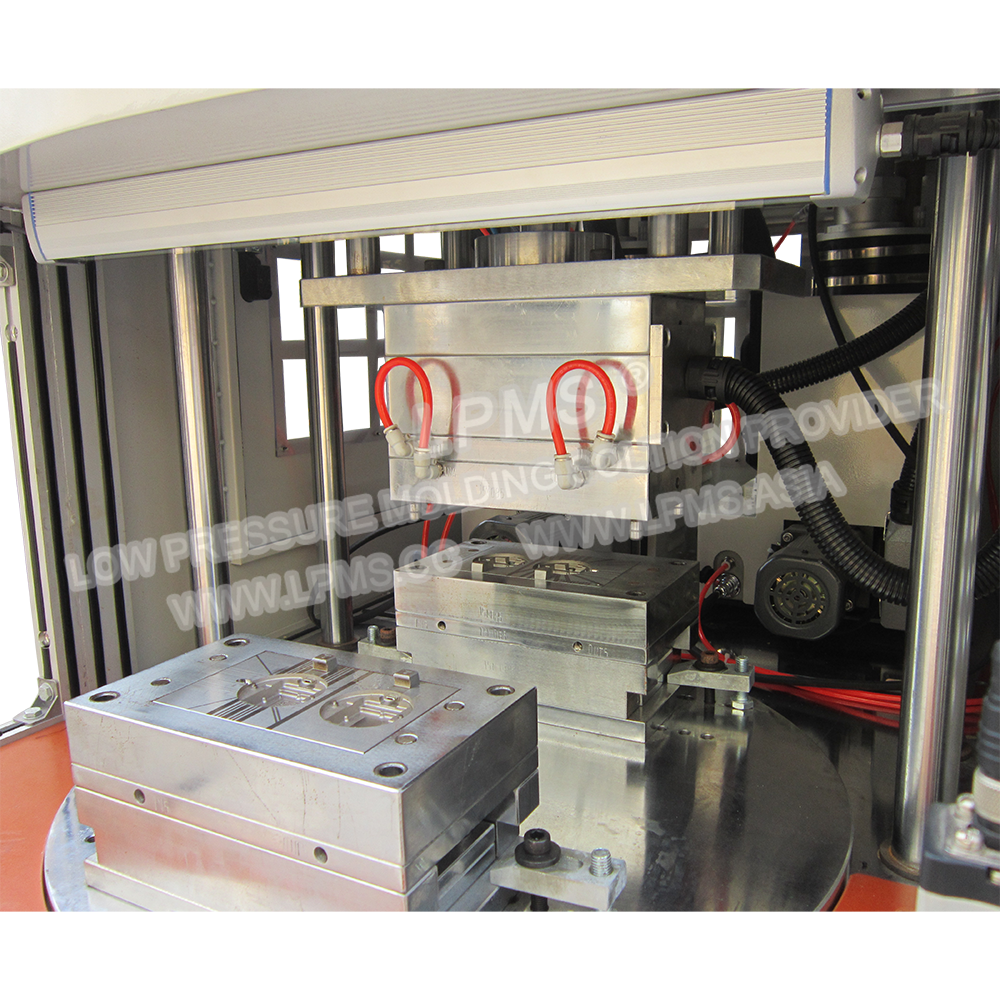

Turntable design. One upper mold serves two bottom molds.

Melt-On-Demand tank melts the resin completely in 18 minutes, taking 6208 hot melt adhesive as example, temperature at 200 °C.

Equipped with dual 1 liter melting tank to fit different color resin or different model resin.

Hot runner system eliminates runner resin and improve productivity.

Built-in chiller.

The only independent dual dispensing low pressure molding system in the industry.

Injection pressure can be adjusted by the touch screen precisely.

Temp in different temp zones like tank, hose, hot runner, hot nozzles can be set independently.

Automatic feeding system and ejection system is equipped.

Application

Our machines are engineered for low pressure molding applications. Using specialty resins to encapsulate delicate parts.

Applications including : automotive electronics, PCBA,coil, fiber-optic, LED lighting, wire, cable, etc.

Specification

Machine Size (Width, Depth, Height) / Weight | 1135 mm x 1442 mm x 1803 mm / 450 kg 44.69 in x 56.77 in x 70.98 in / 992 lbs |

Working Station Height | 850 mm | 33.47 in |

Footprint | 1135 mm x 2100 mm | 44.69 in x 82.67 in |

Packaging Size (Width, Depth, Height) / Weight | 1250 mm x 1560 mm x1850 mm / 500 kg 49.21 in x 61.42 in x 72.83 in / 1102 lbs |

Melting Tank Model & Q'ty | MOD-01-900MD-DSAF x 2 |

Auto Feeding System | Ultrasonic |

Gun Model & Tip | Hot Runner System |

Each Station Gun Tip Q'ty | Std.4,depends on part design |

Heated Hose Model & Q'ty | LPMS-H12J x 2 |

Electricity | 200-240 VAC / 1 Phase / 50 Hz |

Temperature Control Zones | 9 |

Temperature Range | Ambient up to 250°C / 485°F |

Max. Power | 11 Kw |

Min. Air Pressure | 0.5 MPa | 73 Psi |

Air Consumption | 0.1m3/min | 3.53ft3 / min |

Clamping Device | Air Cylinder |

Clamping Force | Max.1.2 Tons |

Clamping Stroke | 75 mm | 2.95 in |

Ejector | Pneumatic |

Ejector Force | 2515 N |

Ejector Stroke | 25 mm | 0.98 in |

Tooling Temp Control | Build-In Chiller |

Control System | PLC+7 in HMI |

Safety Protection | Light Curtain , Safety door |

Standard Mold set Size/Weight | 250 mm x 150 mm x 308mm / 75 kg 9.84 in x 5.91 in x12.13 in / 165 lbs |

Max. Mold set Size | 300 mm x 200 mm x 308 mm 11.81 in x7.87 in x12.13 in |

Max. Part Size | 60 mm x 50 mm x 18 mm 2.36 in x1.97 in x 0.71 in |

Dimension

Video

Copyright ? 2015-2018 LPMS International Ltd. All Rights Reserved.